Surface Inspection

Arcon has developed a range of Inspection Lines to suit the needs of steel suppliers with increasing demands for high quality products for the automotive and white goods markets.

Using the experience gained over many years with major steel suppliers, Arcon supplies lines with manual or fully automatic surface inspection systems. This provides the option of electronically tagging the faulty surface area for use on the next process, or removing the lengths of material for second grade or scrap. The manual inspection systems use strobe lighting and a defect logging system, whereas the fully automatic systems use on-line cameras.

Arcon Inspection Lines can handle coils up to 35 000 kgs in weight, up to 2000 mm in width, and with thicknesses of between 0.3 and 3 mm. Depending on the application, line speeds of up to 500 metres per minute are possible.

Arcon Inspection Lines are designed to meet the requirements of each individual customer and normally include additional features such as tension levelling, re-coiling and edge trimming.

|

ADDITIONAL FEATURES

|

|

-

Tension Levelling

-

Edge Trimming

-

Strip Cleaning

-

Strip Oiling

-

Welding - LOL, Q Mash, Laser

-

Dual Full Grade and

Second Grade Recoiling

-

Thickness Gauge

|

-

Strip material physical properties

measuring system

-

Double unwind/rewind systems

-

Coil Preparation Station

-

Automated coil loading

-

Weighing Systems

-

Strip flatness measuring system

-

Coil Banding facility

|

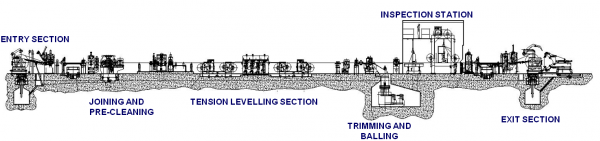

TENSION LEVELLING AND INSPECTION LINES

Arcon has been a supplier of Tension Levelling and Inspection Lines for more than 30 years, with installations worldwide.

Arcon Tension Level Lines are built to process steel with strip widths of up to 1850 mm and thicknesses of between 0.2 and 2.3 mm. Depending on the application, line speeds of up to 300 metres per minute are possible. Using highly advanced Arcon Levelling Technology, flatness of 2 to 3 l-units can be achieved.

RECOILING AND INSPECTION LINES

Recent installations of Arcon Recoiling and Inspection Lines have occurred in India, Iran and Russia. Arcon Recoiling and Inspection Lines have the following main features:

-

Auto Coil Loading

-

Coil Joining by either Welding or Stitching

-

Strip Cleaning

-

Tension Levelling

-

Scrap Rewinding

-

Strip Guiding

-

Edge Trimming

-

Scrap Edge Trim Chopping or Balling

-

Strip Inspection - Horizontal and Vertical

- Inspection lighting

- Camera Inspection

-

Electrostatic Oiling

-

Coil Rewinding

|

ADVANTAGES OF ARCON RECOILING AND INSPECTION LINES

|

-

Improved coil wall build-up

|

-

Flatness improvement: 2 to 3 l units

|

-

Reclamation of prime material

- Remove non-prime material

- Build up prime coil with internal welds

|

-

Edge trim to required width

|

-

Provide auto industry standard inspection facilities

|